The main drawbacks of sequential numbering are that the sequence is predictable and simply replicated, and close people require some implies of entry to the databases. The safer possibility is serialization by means of a pseudo-random non-repeating sequence, and is particularly discussed from the monitor and trace section.

Though passive security labels have already been extensively employed, now just one can find a higher application of useful labels which include printing in addition anti-theft. Some label possibilities are:

These demand a dedicated provide source and enormous volume generation, which, if reasonably priced, brings about an extremely effective option. Micro-encapsulated exclusive odors might be applied as an additive to an ink or coating to deliver a novel covert or semi-overt characteristic, as well as audio chips results in Particular alternatives in the design.

Wong says that the method has long been evaluated for filling a monoclonal antibody and in exploratory studies for vaccines. He claims that a number of applications, starting from early- to late-stage clinical, are using the method.

By knowing your distinct needs, we strive to provide customized packaging remedies that exceed your expectations.

With our experience in customized mold generation, aggressive wholesale pricing, and a strong e-commerce platform, we offer functional options that cater to a variety of industries. Our choices are built to meet your one of a kind prerequisites properly.

Blow fill seal technology is commonly applied and acknowledged by the varied pharmaceutical regulatory authorities as US-FDA and MHRA.

Obviously taking place isotopes are very characteristic from the resource compound, and correctly be determined by laser fluorescence or magnetic resonance tactics.

On-solution marking technologies let for Exclusive images or codes to become placed on standard oral dosage kinds.

The cooling approach begins when the plastic parison leaves the extruder head. The temperature managed metallic copper alloy moulds further keep on the cooling approach because they close and variety the key container. The product or service filled to the container provides ultimate plastic cooling method.

Several parameters influence the temperature of the formulation inside of a BFS course of action. Results was located by actively in controlling the item temperature from more info bulk tank to stage of fill. The temperature impact into the product or service is hereby predictable and right linked to the mass of item being filled in marriage to your plastic container mass.

QCVIALZ presents wanting to fill open sterile vials in nest and tub alveolar trays. Open up nested sterile vials are stored separate with no glass on glass Get in touch with. The alveolar trays may be used like a sterile vial rack while in the compounding laboratory. Nested check here sterile vials present the utmost vial safety.

This aseptic liquid processing technology offers significant strengths about classic filling procedures, mainly because it eradicates opportunity sources of contamination, such as part washing and operator interventions.

Created to increase dependability, Grasp Bond’s line of epoxy underfill compositions offer you great underfill to die passivation together with superb adhesion to several different substrates.

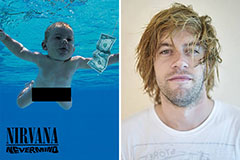

Spencer Elden Then & Now!

Spencer Elden Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now! Ryan Phillippe Then & Now!

Ryan Phillippe Then & Now!